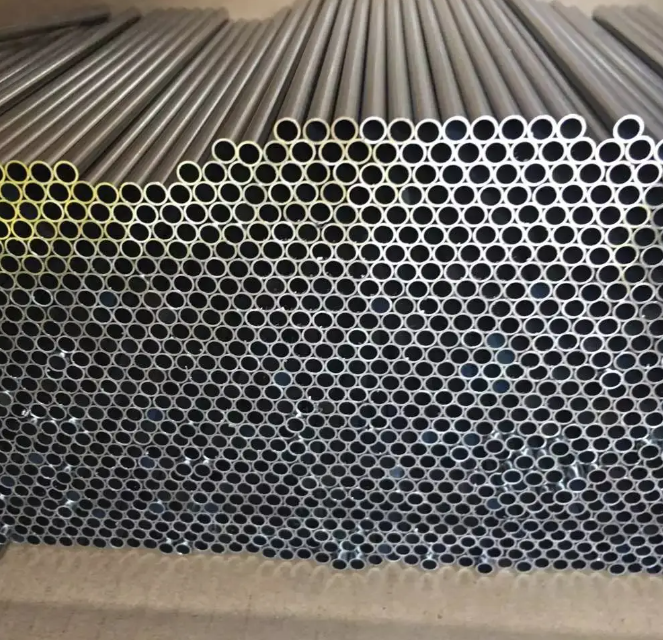

Tervo saldato in acciaio inossidabile di grado 201 304

Ottieni l'ultimo prezzo| Tipo di pagamento: | L/C,T/T,D/P,D/A |

| Incoterm: | FOB,CFR,CIF,EXW |

| Trasporti: | Ocean,Land,Express |

| Tipo di pagamento: | L/C,T/T,D/P,D/A |

| Incoterm: | FOB,CFR,CIF,EXW |

| Trasporti: | Ocean,Land,Express |

Modello: 201 304 304L 316 316L 301 321 410 420 441 439 409L

marchio: Xinsuju

Standard: JIS, AiSi, ASTM, GB, DIN, EN

Luogo D'origine: Cina

Specie: Saldato

Materiale: Serie 200, Serie 300, Serie 400, Serie 600

Certificazione: RoHS, ISO, IBR, BV, Sgs

Forma Della Saldatura: Saldato a spirale, ERW, Efw

Tolleranza: ± 1%

Servizio Di Elaborazione: Flessione, Saldatura, Decoiling, Punzonatura, Taglio, Modanatura

Nome prodotto: Stainless Steel Welded Round Pipe

Moq: 1 ton

Keyword: Stainless steel pipe

Technique: Hot Rolled Or Cold Rolled

Length: 1-12m or customized

Tempi di consegna: 15-30 days

Production Process: welding/ polishing

Size: customized

Surface Finish: 2B

Invoicing: by actual weight

| Unità vendibili | : | Kilogram |

| Tipo pacchetto | : | imballaggio di esportazione standard |

| Esempio immagine | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

|

Product Name

|

Stainless Steel Pipe/Tube

|

|||

|

Technology

|

Hot Rolled Industrial Stainless Steel Tube

Cold Rolled Decorative Stainless Steel Pipe |

|||

|

Material

|

201, 202, 301, 302, 304, 304L, 310S, 316, 316L, 321, 430, 430A, 309S, 2205, 2507, 2520, 430 , 410, 440, 904Lect, Or Customized

|

|||

|

Thickness

|

0.4-50 mm

|

|||

|

Length

|

1-12 m

|

|||

|

Outer Diameter(OD)

|

10-2000mm

|

|||

|

Standard

|

ASTM, JIS, GB, AISI, DIN, BS,EN

|

|||

|

Certifications

|

ISO 9001 BV SGS

|

|||

|

Packing

|

Industry standard packaging or according to client's requirement

|

|||

|

Brand

|

TISCO,ZPSS,Baosteel,POSCO,LISCO,YUSCO,Ansteel, QPSS,JISCO,HXSCO,

Chengde,Yongjin,Tsingshan,Shouyang,HW |

|||

|

Payment terms

|

30%T/T in advance, the balance against the B/L copy

|

|||

|

Delivery time

|

Fast delievery in 7 days,up to order quantity

|

|||

|

Warehose Stcok

|

5000 tons per month

|

|||

|

Surface finish

|

Characteristics & Application

|

|

NO.1

|

Hot-rolled surface,annealed and pickled,can be used as cold-rolling material,industial tanks and chem i cal devices.

|

|

NO.2D

|

Cold-rolled, an nealed and pick led with out skinpassing the dull prod ucts can be used as auto mobile parts, build materrials and pipings.

|

|

NO.2B

|

The surface brightness and flatness of NO.2B is better than NO.2D. Then through a special surfacetreament to improve its mechamical properties, N02B could nearly satisfy com pre hen sive uses.

|

|

NO.3

|

Polished with abra sive belt of grit #100#120,have better bright ness with dis con tin u ous coarse stria, used as inner and external or na ments for building, electrical appliances and kitchen etc.

|

|

NO.4

|

Polished with abrasive belt of grit #150#180, have better brightness with discontinuous coarse stria, but thinner than NO.3, are used as bathtud buildinginner and external ornaments electrical appliances, kitchen utensils and food processing equipment etc.

|

|

HL

|

Polished with abrasive belt of grit #150-320 on the No.4 finish and has continuous streaks, mainly used as building ornaments,elevators, door of building, frontal plate etc.

|

|

BA

|

Cold rolled, bright, annealed, skinned, the product has excellent brightness and good reflectivity, such as mirrors, used in electrical appliances, mirrors, kitchen utensils or clothing materials, etc.

|

|

Austenitic Stainless Steel

|

201, 301, 304, 305, 310, 314, 316, 321, 347, 370, etc

|

|||

|

Martensitic Stainless Steel

|

410, 414, 416, 416, 420, 431, 440A, 440B, 440C, etc

|

|||

|

Duplex Stainless Steel

|

S31803, S32101, S32205, S32304, S32750, etc

|

|||

|

Ferritic Stainless Steel

|

429, 430, 433, 434, 435, 436, 439, etc

|

|||

|

chemical component ( %)

|

|||||||

|

Grade ASTM

|

C

|

Si

|

Mn

|

S

|

P

|

Cr

|

Ni

|

|

201

|

≤0.15

|

≤0.75

|

5.50-7.50

|

≤0.030

|

≤0.060

|

16.00-18.00

|

3.50-5.50

|

|

304

|

≤0.07

|

≤1.00

|

≤2.00

|

≤0.030

|

≤0.035

|

17.00-19.00

|

8.00-11.00

|

|

304L

|

≤0.03

|

≤1.00

|

≤2.00

|

≤0.030

|

≤0.035

|

18.00-20.00

|

8.00-12.00

|

|

309S

|

≤0.08

|

≤1.00

|

≤2.00

|

≤0.030

|

≤0.035

|

22.00-24.00

|

12.00-15.00

|

|

310S

|

≤0.08

|

≤1.00

|

≤2.00

|

≤0.030

|

≤0.035

|

24.00-26.00

|

19.00-22.00

|

|

316

|

≤0.08

|

≤1.00

|

≤2.00

|

≤0.030

|

≤0.045

|

16.00-18.00

|

10.00-14.00

|

|

316L

|

≤0.03

|

≤1.00

|

≤2.00

|

≤0.030

|

≤0.035

|

16.00-18.00

|

12.00-15.00

|

Processo di produzione del tubo in acciaio inossidabile: preparazione di acciaio rotondo - Riscaldamento - Piercing a rotolamento a caldo - taglio della testa - Pickling - macinazione - lubrificazione - trasformazione a freddo - ridotto - Sollease - Soluzione Trattamento termico - raddrizzamento - taglio del tubo - placcatura - ispezione del prodotto finito.

È ampiamente utilizzato nelle condutture di trasmissione industriale e nelle parti strutturali meccaniche come petrolio, industria chimica,

cure mediche, cibo, industria leggera, macchinari e strumenti.

FAQ

D: Qual è il tuo vantaggio?

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.